Gowrings Continental BV was founded in 1973 by the late mr J.A. Steenman with the support of Gowrings Ltd. of Reading in the UK. From 1989 onwards his sons, Joop and Albert Steenman took over the company and developed it into the on- and offshore Gas Turbine maintenance, spares and service company of today’s standards together with a dedicated team.

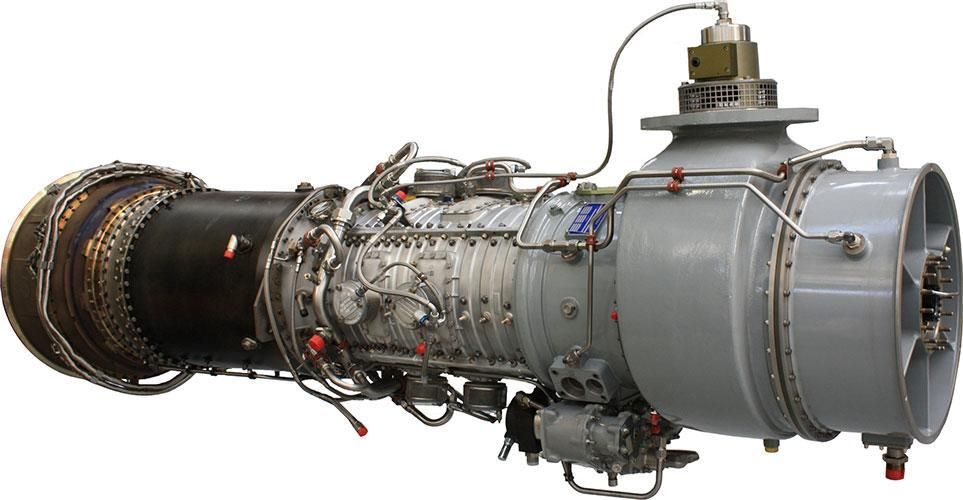

Gowrings Continental BV has worked more then 50 years for the industrial division of Rolls Royce PLC in Ansty, Rolls Wood Group in Aberdeen and what used to be Ruston Gas Turbines and what is now the Siemens Industrial Turbomachinery Ltd. located in Lincoln.

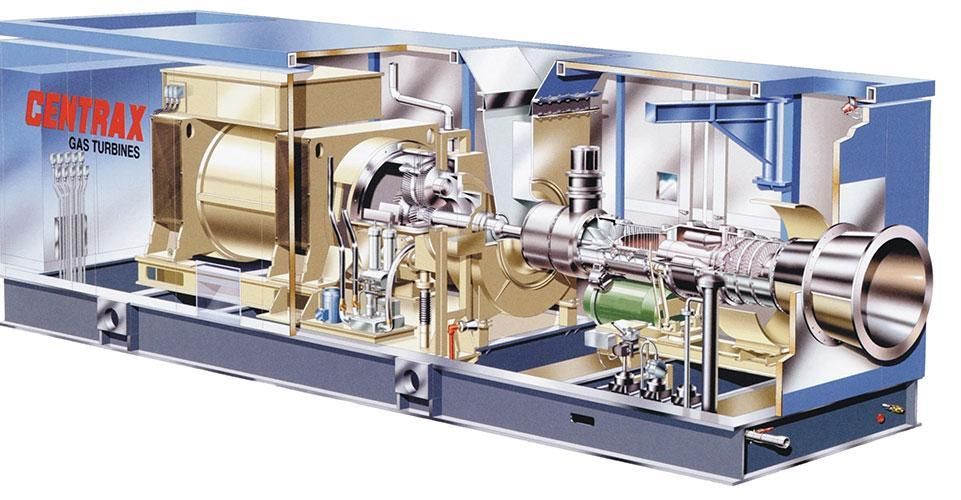

In addition Gowrings Continental represents a world known Gas Turbine packager Centrax from Newton Abbott who are a packager of Gas Turbine gensets in a power range of 3,9 to 64 MW, utilising both RR and Siemens gas turbine driver units.

Gowrings has a gas turbine overhaul facility adjacent to their offices in Maasdam in order to generate a very short turn around time for repair and overhaul work. Gowrings has a long experience in overhauling the Siemens TB, SGT200 and SGT100 engines in their own workshop where they also employ several gas turbine engineers with a great gas turbine multidisciplinary expertise including experienced Control Engineers.

Our company

What we do

Technical support and Field Service

The Gowrings engineers have a wealth of experience in the maintenance of gas turbines and are also specialized in trouble shooting with the support of the latest standard video borescope inspection tools, laser alignment equipment, vibration analysing equipment, star valve calibration equipment and further test calibration kits.

For existing installations which have been maintained by Gowrings, a complete historical database with a predictive maintenance programme and budgetting is available.

For all installations we can provide controls engineers who are fully up to date with the latest controls and software information and provide the ability to “log in” turbine controls on customers sites to investigate technical issues and trendings.

Field service personnel can be made available on very short notice in order to perform ad hoc trouble shooting work, routine scheduled maintenance and full overhauls, such as rotor or gas generator change-outs. This work can be done on the customer premises or in our dedicated workshop.

Gowrings has the ability to “log in” turbine controls on customers sites to investigate technical issues and trendings.

A DNV offshore approved workshop container with tooling and spare parts is available to support any on- and offshore work.

Contact details

Gowrings Continental BV

Postbus 5412

3299 ZG Maasdam

The Netherlands

Visit address:

Lageweg 7

3299 AL Maasdam

The Netherlands

Tel : 0031 78 6768555

Fax : 0031 78 6761223

E-mail : info@gowrings.nl

Joop Steenman

Albert Steenman

Richard Verdonk

Dieter Steenman

Nick Elliott

Mieke van Putten

Marieke Roubos-van Pelt

Mitchel Steenman

Bonnie Steenman

Jon Clifford

Centrax

Centrax Gas Turbines – Power Generation

Centrax Gas Turbines – Power Generation

Centrax manufacture gas turbine power generation packages ranging from 3.9 MW to 64.0 MW for both the Industrial and Oil & Gas energy markets. The prime application for Centrax gas turbine units is Combined Heat & Power (CHP) / Cogeneration in a wide range of industries. In this configuration heat recovery from the gas turbine exhaust can improve the overall plant efficiency to more than 85%.

The generator sets are based on Rolls-Royce 501, RB211 and Trent 60 gas turbines as well as Siemens 300 and 400 gas turbines for the industrial cogeneration market. As well as CHP / Cogeneration plants, Centrax base load and stand-by packages are also in wide use throughout the world.

Power generation packages are available for a wide range of environmental and ambient conditions. The Centrax gas turbine package is designed to operate in the harshest of conditions including very low temperatures (below -50ºC).

Centrax also offers complete turnkey solutions, as well as unparalleled maintenance support backed up with in-country facilities to support our customers throughout the life of their installation.